Today, we’re excited to announce a new chapter as we head into the next 10 years of Able Ebenezer.

Next week, on Monday December 9th, we kick off our new distribution partnership with the NH Beverage Alliance; Bellavance Beverage and New Hampshire Distributors. This move will increase the availability of our brands by bringing them to every corner of the state for the first time in our 10+ year history.

-------------------------

For the past decade, we’ve delivered every ounce of Able beer to our partnered restaurants and retailers ourselves; a challenging effort in the craft beer industry, and one that most scoffed at when we got started in 2014. Many believed our efforts would fail.

In that time, we’ve driven hundreds of thousands of miles to complete well over 20,000 deliveries - totalling over a quarter-million gallons of beer - from our cold rooms here in Merrimack to our partners across the state. In the process, we’ve built relationships and friendships that have become the foundation for our entire business, and ensured Able Ebenezer is a NH brand that will endure for years to come.

The idea to self-distribute at the outset was one we made very deliberately: in the midst of the craft beer boom of the 2010’s, we wanted to prove we belonged in this crowded market, and could hang with the best out there. We had offers from distributors at the start, as most breweries do, but we knew if we were going to stand out amidst the noise we couldn’t just be different; we needed to establish ourselves by doing the hard work to build our own relationships and customer base. Today, I’d say we likely have the most die-hard, loyal customers in the state.

I was the first salesperson and delivery driver when we opened back in 2014. In those days, I spent a lot of time giving away beer to restaurants in hopes that, after enough “no’s,” someone would eventually say “yes.”

There were indeed a lot of “no’s,” but I was able to get 3 “yes’s” at the start: High Street Farmhouse in Goffstown, Country Tavern in Nashua, and NE’s Tap House Grille in Hooksett.

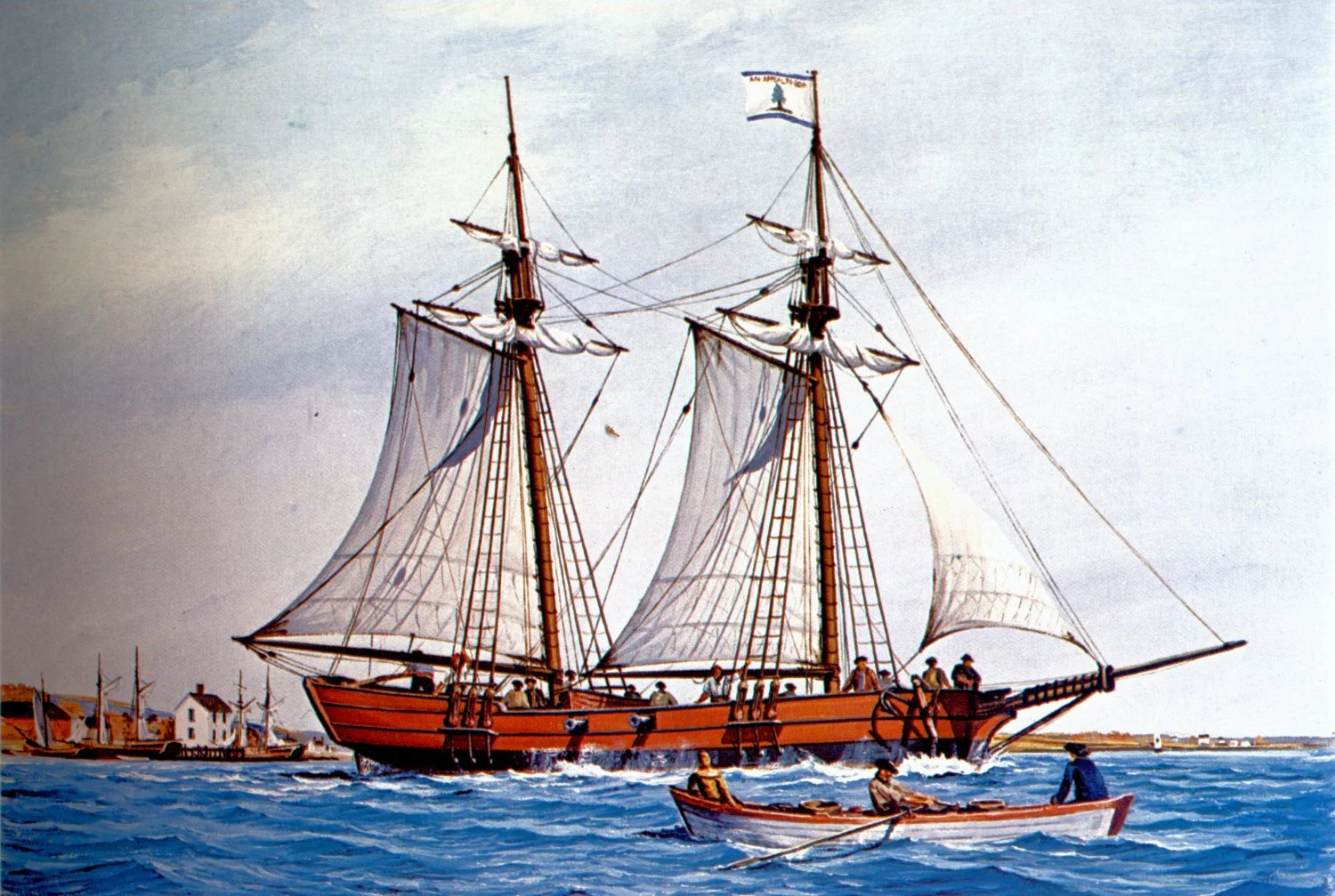

After work each day, I’d go sit at these bars and wait for someone to be indecisive when looking at the beer menu: “if you order a ‘Burn the Ships,’ it’s on me.” I must’ve shared beers and stories with thousands of people over the first several months, then - slowly at first and then suddenly - repeat orders came in. Then restaurants started taking my meetings rather than turning me away, then calls from new restaurants started to come in. It was a huge milestone when we reached 10 accounts, then 20, and before long we had 50 draft lines across the state.

We were able to hire sales & delivery staff, and add a second vehicle. We quickly had to expand our cold room space, buy more kegs and more tanks. After 3 years, we were able to afford our canning line, and could start reaching retail shelves (many forget we were only kegging our beers for the first 3 years). We were then picked up by big chains like Whole Foods Market and Hannaford, and began expanding deliveries to the Seacoast, Monadnock and Lakes regions. Today, we complete 2500-3000 deliveries a year to the hundreds of partnered accounts we have across the state.

Add into that the tough covid years, when we pivoted our self-distro operation to deliver 4-packs to your front doors. That pivot not only saved the company, but allowed us to keep our entire staff on payroll; believe it or not, April and May 2020 remain two of the top 5 sales months in Able’s history. We still have that core staff in place today, and I cannot stress enough how important not having to replace them has been.

After all, you can’t just replace family, right?

Thus, over the past 10 years, I think we’ve proven we belong in this market - both in the quality of our products and our service - and have built a strong foundation from which we can venture forth into the next chapter of Able Ebenezer.

Similar to the deliberate decision we made over 10 years ago to commit to self-distribute, the decision to enter this new partnership was also not made lightly.

Self-distribution is hard, and has its limits: we aren’t able to reach a great deal of the state, or gain access to draft lines and shelves managed by corporate entities who prefer to work with the large distributors; and honestly I can’t blame them: adding a 3rd vendor to the rolls for just 1 or 2 brands doesn’t make a lot of business sense at a certain level. In addition, we have to maintain our own (cold) inventory at all times, and cover all the logistics costs like fuel, insurance, maintenance etc.

We knew the day would eventually come when we would outgrow our self-distro model if we wanted to bring Able to the entirety of New Hampshire, and we feel that day is finally upon us.

-------------------------

There’s two military concepts that come to mind in this moment:

The first is Force Multiplication: a factor or a combination of factors that gives us the ability to accomplish greater feats than without them. This new partnership allows us to multiply our efforts, adding personnel, vehicles, cold room space (BBC has the biggest cold room I’ve ever seen btw), time, resources and more to our operation. Availability of our products will also increase dramatically: you’ll see more draft lines, more shelf placements and more regularly stocked shelves.

The other is Tactical patience: having the discipline to set conditions for success before making your move to accomplish the mission. We’ve been tactically patient for over 10 years now, and now the conditions couldn’t be more in our favor: while the overall beer market nationally has continued to shrink over the past few years, we continue to see steadily growing demand. We simply don’t have the bandwidth to fulfill it. The most important condition, however, is we can now make this shift without sacrificing any of the aspects that got us here in the first place.

With that, while we are handing over the keys to our distribution operation (a full 1/3rd of the work done at Able), there will be no change to our team; everyone will stay aboard and remain in the fight. We will simply have more time to dedicate to being in the market and maintaining the relationships we’ve built over the years while also being able to build new ones…as well as more personal time to spend with family and friends.

Which brings us to Bellavance & NHD: In selecting our new partner, we wanted someone who would take the same care of our products that we have for 10 years: beer kept cold, delivered when needed, and by people who love and respect the industry.

The people at Bellavance/NHD have been friends and supporters of us since the beginning, inviting us to their events, and always happy to sit down and answer questions about the industry, even though we technically competed directly in the market. In short: they’ve always treated us as professionals and equals, which means a lot when you're a rag-tag startup distributing your own products against a 100+ year old company with the largest brewer in the world on their side. We’re both excited to take what we’ve built thus far and bring our work to the next level.

So yeah, big shoutout to Dan Taylor & friends for being absolute rockstars to us over the past decade.

-------------------------

Thus, our last day of deliveries will be on Friday, December 6th, bringing an end to the first chapter in the story of Able Ebenezer. We hope you’ll join us at the bar as our trucks come off the road from their routes for the last time.

While there is a lot we will miss about self-distro, we’ll never forget those special moments that brought us to where we are today, and are excited about the next chapter ahead. Rest assured, Chapter 2 will be even better.

Thank you all for your continued love and support; at the end of the day, none of this would be possible without you. We look forward to the road ahead, and are stoked to have you alongside us on this journey. Cheers 🍻

-Carl

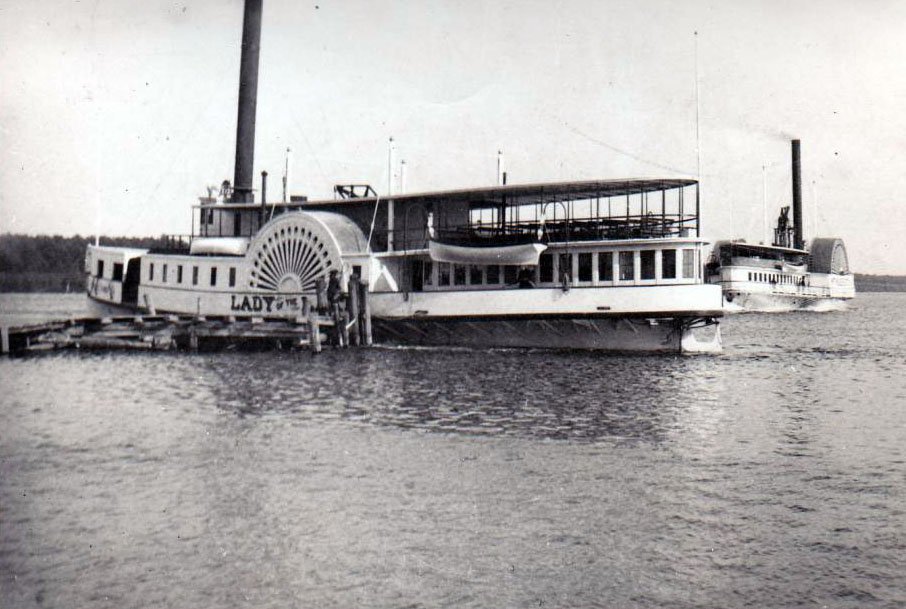

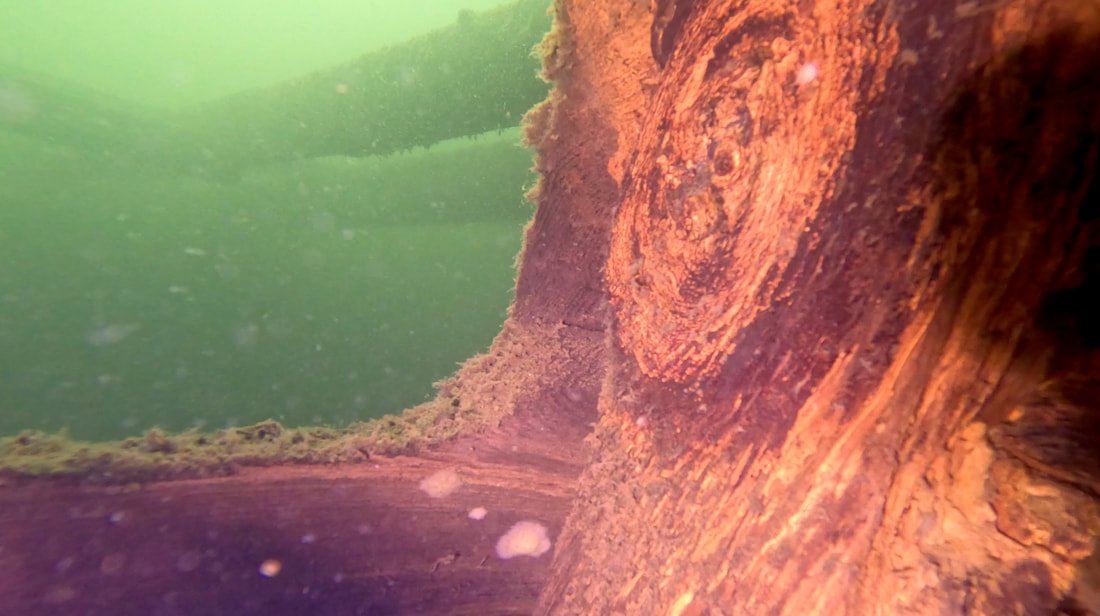

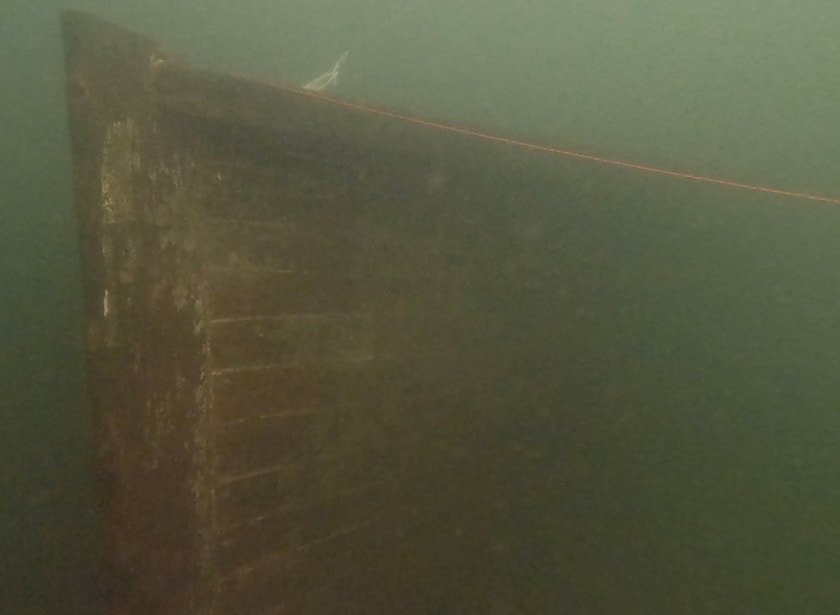

including these just cause they make me happy